11 parameters to characterise your laser system

Laser systems have become indispensable tools across industries due to their precision and versatility. Behind their remarkable performance lie a set of key parameters that engineers and operators must comprehend for optimal utilization. In this comprehensive exploration, we delve into each of the seven key parameters shaping the dynamics of laser systems.

1. Wavelength

A laser’s wavelength describes the spatial frequency of the emitted light wave. Wavelength serves as the foundational element, determining how a laser beam interacts with materials. Measured in nanometers (nm) to micrometers (µm), the wavelength influences absorption characteristics, making it essential for selecting a wavelength tailored to the material being processed. Different wavelengths cater to diverse applications, from the ultraviolet (UV) range for high-precision micro-machining to the infrared (IR) range for cutting and welding.

2. Power and Energy

Laser power, quantified in watts (W), represents the energy delivered per unit of time. Power dictates the intensity of the laser beam, impacting material processing capabilities. Low-power lasers find utility in delicate tasks like engraving, while high-power lasers are deployed for robust applications such as metal cutting. Fine-tuning laser power ensures optimal performance for specific tasks.

The power is used to describe either the optical power output of a continuous wave (CW) laser or the average power of a pulsed laser. Pulsed lasers are also characterized by their pulse energy, measured in joules (J), which is directly proportional to average power and inversely proportional to the laser’s repetition rate (Pulse Energy=Average Power/Repetition Rate)

Higher power and energy lasers are typically more expensive, and they generate more waste heat. As powers and energy increase, it also becomes increasingly more difficult to maintain high beam quality.

⇒ More information on pulsed and CW lasers can be found in Edmund Optics Application note Understanding and Specifying LIDT of Laser Components.

3. Pulse Duration (Pulse width)

Pulse duration (pulse width), measured in picoseconds (ps), nanoseconds (ns), or microseconds (µs), defines the temporal length of a laser pulse in pulsed laser systems. This parameter is critical for applications like laser micromachining and material ablation. Shorter pulse durations minimize heat transfer, enabling precision work and minimizing the heat-affected zone.

The laser pulse duration is commonly defined as the full width at half-maximum (FWHM) of the laser’s optical power vs. time.

Ultrafast lasers, which have numerous benefits for a range of applications including precise materials processing and medical lasers, are characterized by short pulse durations on the order of picoseconds (10-12 s) to attoseconds (10-18 s).

⇒ More information can be found in Edmund Optics Ultrafast Dispersion and Highly-Dispersive Mirrors application notes.

4. Repetition Rate (Pulse repetition frequency)

Expressed in hertz (Hz), the repetition rate signifies the number of laser pulses delivered per second or the inverse temporal pulse spacing. This parameter is pivotal for applications requiring high-speed processing, such as laser marking on production lines. Adjusting the repetition rate provides control over material interaction and allows customization based on specific industrial requirements. Higher repetition rates result in less thermal relaxation time at the surfaces of the laser optics and at the final focused spot, which leads to more rapid material heating.

Repetition rate is inversely proportional to pulse energy and directly proportional to average power. While repetition rate is often dependent on the laser gain medium, in many cases it can be varied.

5. Polarisation

Polarization characterizes the orientation of the electric field associated with light waves, and this orientation is consistently perpendicular to the direction of propagation. In many instances, laser light exhibits linear polarization, indicating that the emitted electric fields consistently align in a specific direction. In contrast, unpolarized light features electric fields oriented in various directions.

The extent of polarization is commonly quantified by expressing it as a ratio of the optical power associated with two orthogonal polarization states. This ratio is often denoted as, for example, 100:1 or 500:1, signifying the relative strength or dominance of one polarization state over the other. This measure provides a quantitative understanding of the degree to which the laser light is polarized and is instrumental in assessing and optimizing the performance of laser systems for specific applications.

⇒ For more information about polarization please check Edmund Optics Application note Introduction to Polarization.

Beam Parameters

6. Beam profile

The beam profile illustrates the spatial distribution of laser intensity across the beam's cross-section. Common profiles include Gaussian, top-hat, and ring profiles. The choice of beam profile is tailored to specific applications, influencing factors such as cutting efficiency, depth of focus, and heat distribution. For instance, a uniform top-hat profile might be favored in applications requiring consistent material removal.

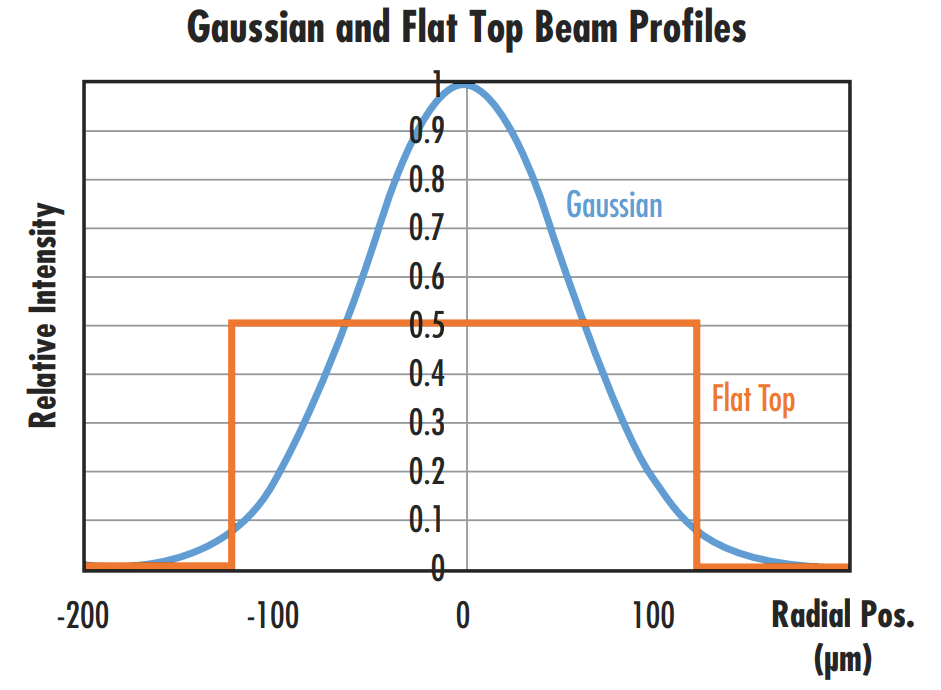

A laser’s beam profile describes the distribution intensity at a cross-section of the beam. Common beam profiles include Gaussian and flat top beams, whose beam profiles follow Gaussian and flat top functions, respectively (see Figure below). However, no laser can produce a perfectly Gaussian or perfectly flat top beam whose beam profile matches its characteristic function perfectly, as there is always some amount of hotspots or fluctuations inside a laser. The difference between a laser’s actual beam profile and that of an ideal beam is often described through metrics including a laser’s M2 factor.

A comparison of the beam profiles of Gaussian and flat top beams with the same average power or intensity shows that the Gaussian beam will have a peak intensity 2X that of the flat top beam (Edmund Optics Application Note: Key Parameters of a Laser System)

7. Beam Size

The beam diameter of a laser, typically measured in millimeters to centimeters, characterizes the transverse extension of the beam—the physical size perpendicular to the direction of propagation. This parameter is often defined at the 1/e² width, indicating the region where the beam's intensity drops to approximately 13.5% of its maximum value.

At the 1/e² point, the electric field strength decreases to 1/e, or approximately 37% of the maximum value. The significance of beam diameter lies in its influence on the overall system design. A larger beam diameter necessitates larger optics and an expanded system to avoid clipping the beam, thereby adding to the cost. Conversely, reducing the beam diameter increases power/energy density, a factor that can have both advantages and disadvantages depending on the specific application. Careful consideration of beam diameter is essential in optimizing laser system performance while balancing costs and potential trade-offs.

8. Power or Energy Density

The beam diameter plays a crucial role in determining the power/energy density of a laser beam , representing the optical power/energy distributed per unit area (typically W/cm² to MW/cm² or µJ/cm² to J/cm²). In cases where the beam diameter is larger, the power/energy density decreases for a laser beam with constant power or energy. While high power/energy densities are often desirable at the final output of a system, such as in laser cutting or welding applications, maintaining lower power/energy densities within the system is beneficial. This precautionary measure helps prevent laser-induced damage and mitigates the risk of high power/energy density regions ionizing the surrounding air.

To achieve a balance between high and low power/energy densities, laser beam expanders are frequently employed. These devices increase the beam diameter, consequently decreasing the power/energy density within the laser system. This adjustment is particularly crucial for internal components to ensure optimal performance and prevent potential damage. It is worth noting that caution must be exercised to avoid excessive beam expansion, which can lead to clipping at apertures within the system, resulting in wasted energy and the risk of damage. Detailed insights into managing beam diameter and power/energy density contribute to the efficient and safe operation of laser systems. For further guidance, refer to Edmund Optics Laser Beam Expanders application note.

9. Beam Divergence

Laser divergence, another significant parameter, refers to the spread of the laser beam as it propagates away from the source. Laser divergence is influenced by factors such as the wavelength and the size of the laser aperture. Understanding and controlling laser divergence is crucial for optimizing performance in various applications. Divergence becomes an especially significant issues in applications with a long working distance, such as LIDAR systems where an object may be hundreds of meters away from the laser system. Beam divergence is typically defined by the laser’s half angle, and the divergence (θ) of a Gaussian beam is defined as: θ=λπw0, where λ is the laser’s wavelength and w0 is the laser’s beam waist.

⇒ More information about divergence can be found in Edmund Optics Application note Gaussian Beam Propagation.

⇒ Divergence can be decreased by increasing the beam diameter, as described in Edmund Optics Application note Laser Beam Expanders.

When selecting a laser system, it's crucial to recognize that several additional parameters play pivotal roles in optimizing performance for specific applications. Beyond parameters mentioned above factors such as working distance and spot size demand careful consideration.

10. Spot Size

Spot size refers to the diameter of the laser beam at its focal point of a focusing lens system. It directly influences the precision of material processing. A smaller spot size is advantageous for intricate tasks like medical surgery or laser engraving, enabling detailed work (maximizes power density and allows for the creation of especially fine features), while a larger spot size may be suitable for rapid material removal in tasks like welding or surface treatment.

11. Working distance

The working distance, typically measured in units ranging from micrometers (µm) to meters (m), is a crucial parameter in laser systems. It is commonly defined as the physical distance from the final optical element, usually a focusing lens, to the object or surface onto which the laser is focused.

In specific applications like medical lasers, the objective is often to minimize the working distance. Conversely, in applications like remote sensing, the goal is frequently to maximize the working distance range. This distinction in approach highlights the varied requirements and considerations that different laser applications demand.

A nuanced understanding of these key parameters is imperative for harnessing the full potential of laser systems in the dynamic landscape of modern industry. As technology advances, mastering these intricacies becomes not only a technical necessity but also a pathway to unlocking new possibilities in precision manufacturing, material processing, and beyond.

Date

01 February 2024Tags

Laser parametersHeard on the Internet

Imagination is more important than knowledge.

Albert Einstein